With the fast-moving and increasingly regulated sustainability landscape of today, it is challenging to remember what the labeling and packaging industries looked like a decade ago. Environmental concerns were not in the mainstream, but frontrunners were paving the way. Gabriela Neves Ferri, Vice President, Global R&D and Sustainability of All4Labels, reminisces:

“I remember very well that UPM Raflatac was the first to launch and promote an LCA tool in the labels market. It was a coincidence that in 2014, we were also looking to develop a model to measure the environmental impact of printed labels.”

The collaboration between UPM Raflatac’s LCA service Label Life and All4Labels was thus a fitting match. Already 10 years ago, All4Labels was a global player in the label industry with a growing emphasis on digital solutions and sustainability. When it came to developing their own modelling, Label Life could provide the company the carbon footprint, energy demand, and water consumption of label materials based on primary data, and thus, high credibility.

The collaboration however extended beyond the exchange of facts and figures. Gabriela describes:

“Since the beginning, Label Life was an amazing inspiration for us and designed to be very dynamic. Our desire was to develop something similar for printing technologies, and despite some learning curves the UPM Raflatac team has been supportive every step of the way.”

Partnerships help respond to industry shifts and demands

Today, Life Cycle Assessment is the norm for calculating the environmental impact of products from cradle-to-grave. Gabriela sees that the emphasis on environmental concerns has completely shifted the way the industry develops labels:

“Some 6 years ago the industry was talking about embellishments for labels, not recyclability or emissions. For us, LCA data by Label Life has supported and guided our decision-making and R&D towards more sustainable packaging solutions.”

According to Gabriela, customers and brand-owners trust converters to respond to shifts in the sustainability landscape. Long-lasting partnerships further increase this trust and help create business.

“Transparency and externally validated data sources are really important to avoid greenwashing. It is expected and appreciated by customers”, Gabriela adds in reference to Label Life’s DEKRA validation, received in 2023.

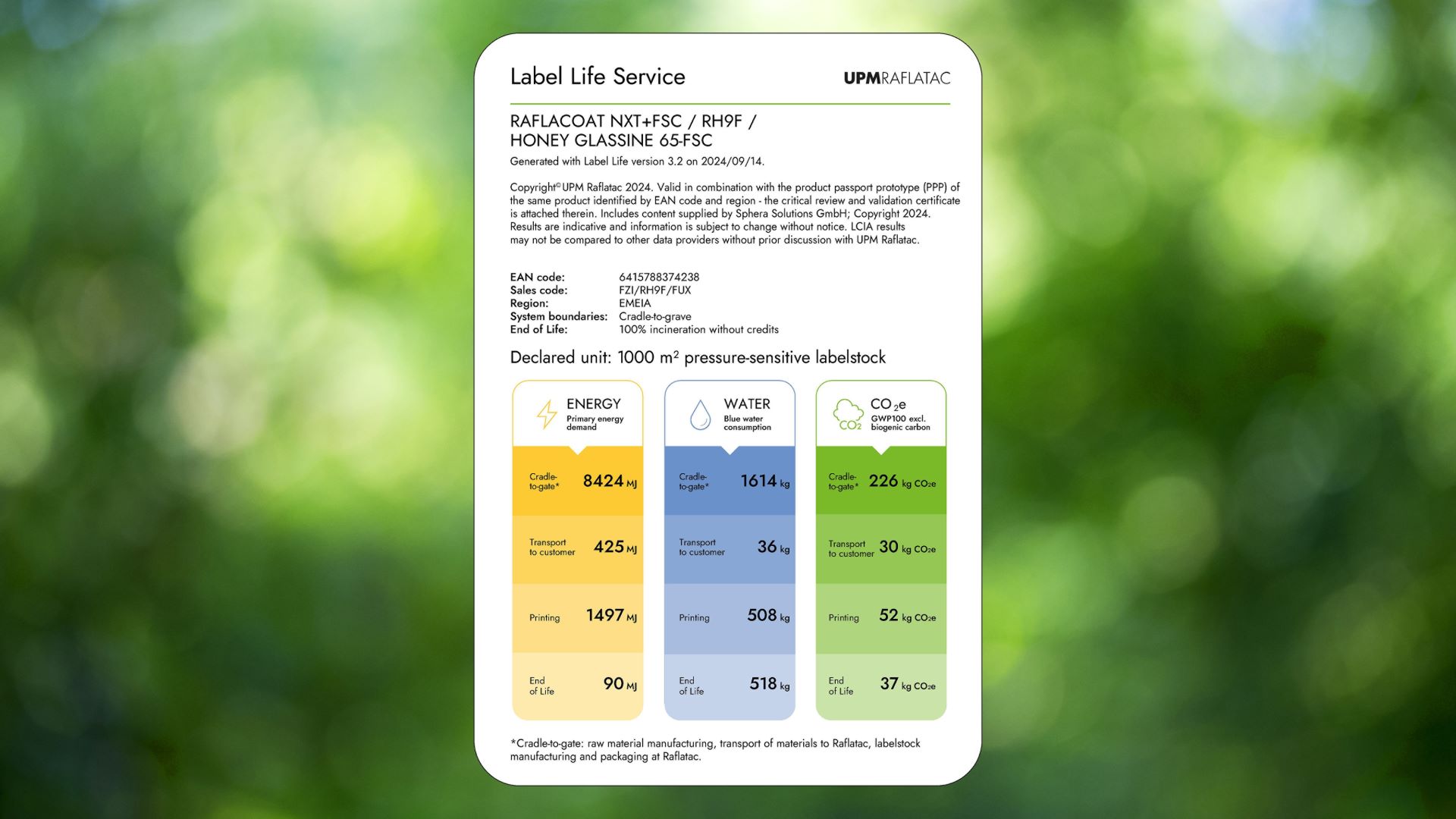

Label Life summary of the environmental information of UPM Raflatac RAFNXT+, a lower-carbon alternative to traditional labeling materials. All4Labels has switched to RAFNXT+ to improve their carbon footprint.

Scope 3 in the spotlight

During the past few years, brand-owners have increasingly turned their attention to Scope 3 emissions*, which has manifested as pressures all throughout the value chain. In the packaging industry, raw materials account for the bulk of Scope 3 emissions, and reducing these emissions is often not as straightforward, as expected. Gabriela explains:

“Downgauging the material in a label or package might not automatically mean, that the carbon footprint decreases. Being able to discuss cases like these together with the UPM Raflatac team, we have been able to better advise our customers on how to reach their sustainability goals.”

The journey towards a more sustainable future continues

Gabriela is conscious of keeping the bigger picture in mind instead of limiting perspective to product-level comparisons:

“All4Labels and UPM Raflatac share the view that labels have a significant impact on packaging sustainability, not only in terms of environmental impact but also in supporting recyclability and the transition to a circular economy.”

All4Labels is also helping their customers recycle label release liner waste with UPM Raflatac’s RafCycle service. The annual recycling potential with six of their customers in total is approximately 100 tonnes, including glassine liner and PET liner.

“Sustainability is a long journey all about collaboration. With new regulation and shifts in the landscape, the next decade holds more and more opportunities to continue our journey together”, Gabriela concludes.

* Scope 3 refers to indirect emissions that occur in the value chain of a company, including both upstream and downstream emissions.